Desiccant Masterbatch is used in removing moisture from the plastic materials in various industries. It is made using various combination of chemicals and compounds. It removed moisture from reprocess polymers.

Before using raw materials, moisture needs to be removed from them. If we talk of raw material, they are like Pigments, fillers, hygyroscopic polymers, etc. As, this raw material have high level of moisture content, it needs to be soaked using high quality desiccant masterbatches.

Vardhman Enterprises Desiccant Masterbatches consists of high quality Calcium Oxide minerals. These Desiccant masterbatches completely removes all moisture from virgin and recyled PP, LD, LLDPE, HDPE, HM, etc and are used in Blown Film Plants, raffia and as well as in moulding.

Not only but also, our Desiccant masterbatches completely remove Fish Eyes, Silver Streak in molding, Windows, lenses in films, porosity, etc.

We have very high quality desiccant masterbatches, which give Increased filler addition level, helps in maintaining strenght and also increase reprocess polymer addition level.

Some Questions Asked By Buyers Before Buying Desiccant Masterbatches As Below:

| Which Brand? | Vardhman |

| What is Corrosion Type | Corrosion less |

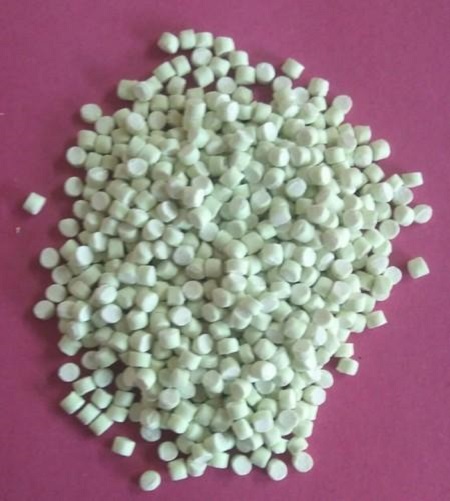

| Which Form or shape? | Round Pellet |

| Which Material uses? | PE |

| What will be the Pack Size? | 1kg, 5 kg, 10kg, 15kg |

| What will the Pack Type? | High Quality |

| How much is the Carbon Content? | Zero |

| What type of Carrier Resin? | PE |

| What is the color ? | white |

| What will be the Ageing time? | 6 months if packed and not opened |

| What will be the Bulk Density? | 1.100 +/- 0.100 gm/ml |

| What type of Compliances? | FOOD GRADE |

| What temperature Stability? | 300 C |

| What will be the Melting Point? | 130°C +/- 10°C |

| What will be the Physical State? | Solid |

| How much Moisture level? | 0.10 % Max |

| What will be the Packaging Type? | Bag packing |